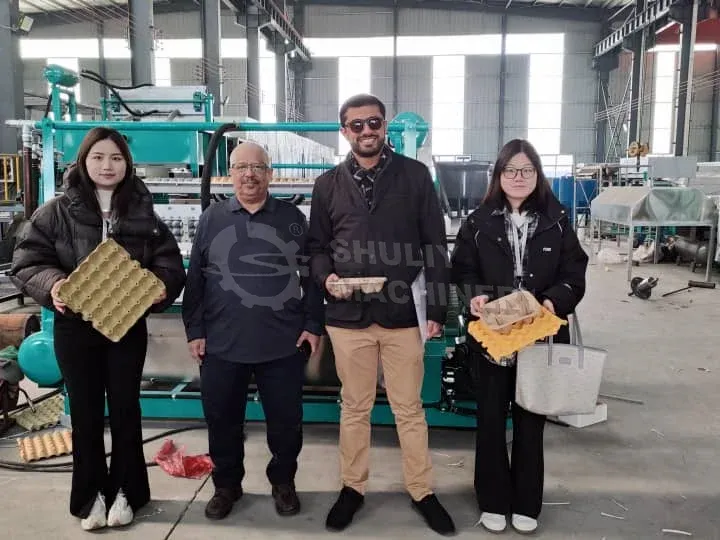

Shuliy 1500pcs/h egg crate making machine in Sri Lanka for self-made paper trays

- Project name: Egg crate making machine plant

- Client: Chicken farm owner

- Location: Sri Lanka

This Sri Lankan client operates a chicken farm, supplying eggs in the local market. With increasing egg sales, the client aims to establish an in-house egg crate production line to ensure a stable supply, reduce long-term costs associated with purchasing trays externally, and enhance packaging control.

Análisis de los requisitos principales del cliente

During preliminary discussions, the client emphasized the following priorities:

- Consistent output to meet daily egg packaging demands

- Continuous production capability unaffected by weather conditions

- Simple operation and easy maintenance suitable for local workers

- Compatibility with local voltage to ensure long-term stable equipment operation

Based on these requirements, the client explicitly sought a mature, reliable egg carton tray production solution tailored to Sri Lanka’s climate conditions.

Equipment configuration: 1500pcs/h egg crate making machine & trolley dryer

Based on the client’s specific requirements, we recommended and ultimately secured an order for a 1500pcs/h egg tray making machine with trolley dryer.

This configuration strikes an optimal balance between production capacity and investment cost, meeting daily production demands without requiring excessive initial capital outlay. It is highly suitable for small to medium-sized egg crate tray production projects in Sri Lanka.

The trolley drying system enables simultaneous drying of multiple paper trays, offering high drying efficiency and stable operation. It effectively avoids issues associated with natural air-drying, such as disruption by rainy seasons and humidity fluctuations.

Why is trolley drying more suitable for the Sri Lankan market?

Sri Lanka experiences a high-humidity, rainy climate where natural air-drying is unreliable, often compromising egg tray drying quality and production consistency. The cart-based drying system offers the following advantages:

- Weather-independent operation, enabling year-round continuous production

- Uniform drying, ensuring well-formed egg trays with minimal deformation

- Simple operation with low labor costs

This is also a key reason why Sri Lankan customers frequently search for and prioritize “egg tray machine with dryer” during selection.

Final purchase order

- Egg carton making machine: 1 set

- Paper pulper: 1 set

- Trolley dryer: 1 set

- Hot pressing machine: 1 set

Solution tailored for Sri Lankan clients

Through the 1500pcs/h egg tray machine + cart drying system, this Sri Lankan client has successfully established a stable egg tray production capacity. This configuration is highly suitable for:

- Local poultry farms

- Egg wholesalers and retailers

- Entrepreneurs planning to enter the egg tray manufacturing industry

Obtain an egg tray machine solution suited for your country!

If you wish to learn about pricing and configurations for the 1500pcs/h egg tray machine, please contact us. We can customize the most suitable egg tray production solution based on your country, voltage requirements, output capacity, and budget.