Nini kinachoweza kuathiri bei ya mashine ya kutengeneza tray za mayai?

Med den växande efterfrågan på miljövänlig förpackning ökar marknadsintresset för egg traymaking machines snabbt. För de som är intresserade av att investera i denna industri är det viktigt att förstå faktorerna som bidrar till priset på en äggbrickemaskin och att välja en ansedd tillverkare.

I den här artikeln kommer vi att introducera dessa två aspekter för din referens när du köper en pappersbricka tillverkningsmaskin.

Faktorer som påverkar priset på maskiner för tillverkning av äggkartonger

Uwezo wa uzalishaji

Uwezo wa uzalishaji wa mashine ya tray ya mayai ndiyo sababu kuu ya kuamua bei. Vifaa vya soko vya sasa vinatofautiana kutoka vipande 1,000 hadi 7,000 kwa saa. Kadri uwezo unavyoongezeka, ndivyo muundo wa mashine unavyokuwa mgumu zaidi, mahitaji ya usanidi yanavyoongezeka, bei kwa asili inapaa.

Till exempel,

- En liten äggbricka maskin med 1000st/h är lämplig för nystartade företag eller hönsfarmar, och priset är relativt överkomligt.

- En helt automatisk produktionslinje med 5000st/h eller mer är mer lämplig för storskaliga fabriker, och priset är också högre.

Kiwango cha automatisering

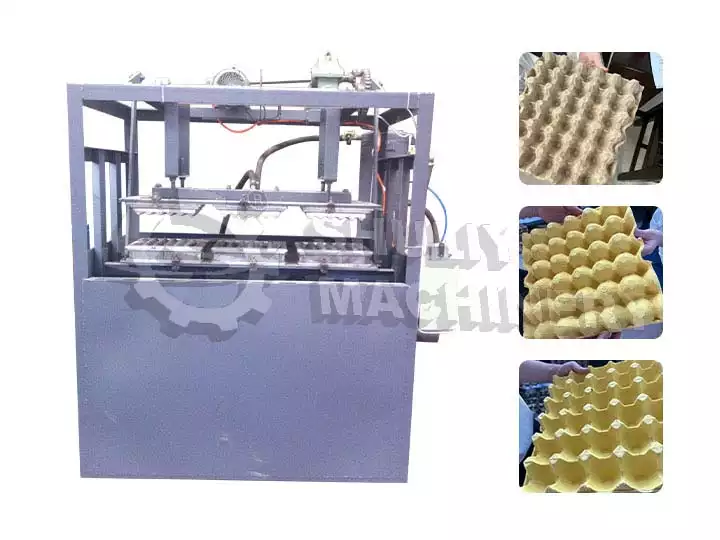

Äggbricka maskiner delas in i två typer: semi-automatisk och helt automatisk.

- Mashine ya tray ya mayai ya nusu-otomatiki kwa ujumla inatumia mfumo wa kukausha wa asili au mfumo rahisi wa kukausha, gharama ya vifaa ni ya chini, inafaa kwa uwekezaji wa awali wa wateja wadogo.

- Linia ya uzalishaji ya tray za mayai ya kiotomatiki kabisa, kwa upande mwingine, inajumuisha mfumo wa kusaga, mfumo wa umbo, mfumo wa kukausha kiotomatiki na mfumo wa kufunga, ambao unahifadhi kazi na kuboresha ufanisi. Bei ya mashine ya kutengeneza tray za mayai itainuliwa ipasavyo.

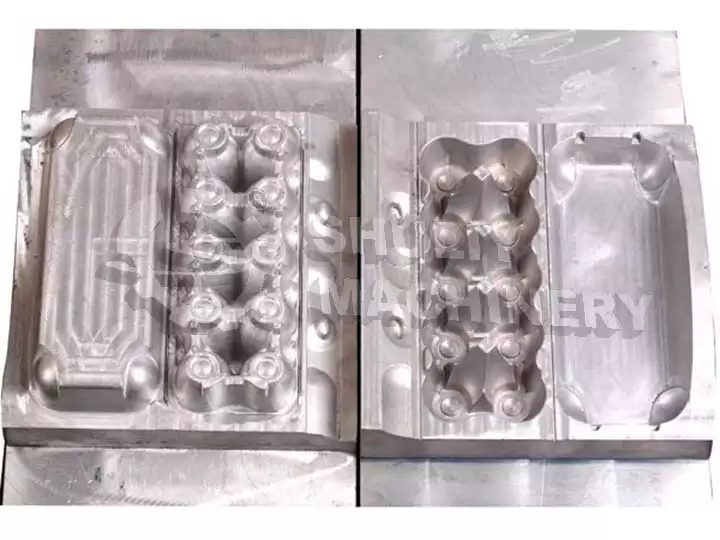

Tillbehörsmaterial och typ av form

Nyenzo ya ukingo imegawanywa katika ukingo wa plastiki na ukingo wa alumini. Ingawa ukingo wa alumini unagharimu zaidi, lakini una maisha marefu, na bidhaa iliyomalizika ina uzuri zaidi.

Torkmetod för äggkartonger

I produktionen av äggbrickor kommer valet av torkningssystem att påverka den totala kostnaden för hela produktionslinjen avsevärt.

- Naturlig torkning kräver ingen extra utrustning och är lämplig för soliga och rymliga områden med låga totala kostnader.

- Torkning i tegelugn är lämplig för kunder med medelstora produktionsvolymer, med måttliga kostnader och kontinuerlig drift.

- Mfumo wa kukausha chuma ni suluhisho la moja kwa moja lenye ufanisi mkubwa ambalo linachukua eneo dogo, linakauka haraka. Inafaa kwa uzalishaji wa kiwango kikubwa, lakini uwekezaji katika vifaa ni wa juu kidogo.

Dessutom kommer konfigurationer som spänning och motorvarumärke i olika regioner också att orsaka prisvariationer på äggbricka tillverkningsmaskiner.

Varför välja Shuliy's maskin för äggkartonger?

Shuliy Machinery ina uzoefu wa miongo kadhaa katika utengenezaji wa vifaa vya umbo la pulp na bidhaa zetu zinauzwa nje katika zaidi ya nchi 60 duniani. Faida zetu ni:

- Erbjud en helhetslösning från massaproduktion till formning och torkning.

- Mifumo maalum, voltage na mbinu za kukausha zinapatikana kulingana na mahitaji ya wateja

- Huduma bora baada ya mauzo, ikiwa ni pamoja na mwongozo wa usakinishaji, mafundisho ya video, na msaada wa usafirishaji wa forodha

- Bei ya moja kwa moja kutoka kiwandani, ubora wa kuaminika na ufanisi wa juu wa gharama

Om du överväger att investera i ett projekt för att tillverka äggtråg, rekommenderar vi att du kommunicerar med vårt professionella Shuliy-team för att få en personlig konfigurationsplan och en exakt offert. Tveka inte att kontakta oss för mer information!