Gharama ya mashine ya kutengeneza tray za mayai ni kiasi gani?

Kwa kuongezeka kwa mahitaji ya ufungaji rafiki kwa mazingira, wateja wengi zaidi wanazingatia gharama za mashine za kutengeneza sahani za mayai. Hivyo, ni vipengele gani vinavyoathiri kabisa bei za mashine za sahani za mayai? Kwa nini kuchagua mashine za kutengeneza sahani za mayai za Shuliy ni vyema zaidi?

Uwezo wa uzalishaji: kigezo kikuu kinachoamua bei

Bei ya mashine ya karatasi ya mayai inategemea hasa uwezo wake wa uzalishaji.

- Mashine za kiwango kidogo zinazozalisha sahani 1000-1500 kwa saa zinahitaji uwekezaji mdogo na zinafaa wajasiriamali wa mwanzo au shamba ndogo ndogo.

- Mstari wa uzalishaji wa ukubwa wa kati wenye uwezo wa 2000-3500 sahani kwa saa unalenga biashara za kati.

- Mstari kamili wa uzalishaji wa moja kwa moja wa kiwango kikubwa unaoweza kutengeneza sahani 4000-7000 kwa saa unakidhi mahitaji ya uzalishaji unaoendelea ya viwanda vikubwa, hivyo kwa kawaida unaagiza bei ya juu.

Njia ya kukausha: kuathiri gharama

Miongoni mwa mambo yanayoathiri gharama ya mashine za kutengeneza sahani za mayai, njia ya kukaushia ni mojawapo muhimu.

- Kukaushi kwa hewa ya asili hakuhitaji karibu uwekezaji wa ziada lakini kunategemea sana hali ya hewa.

- Kukaushia katika tanuri la matofali kunatoa gharama za wastani na kunafaa watumiaji wa uzalishaji wa kati.

- Mifumo ya kukaushia kwa chuma, ingawa yanahitaji uwekezaji mkubwa wa awali, huleta ufanisi wa juu na hufanya kazi bila kujali hali ya mazingira, ukiyafanya kuwa bora kwa uzalishaji mkubwa unaoendelea.

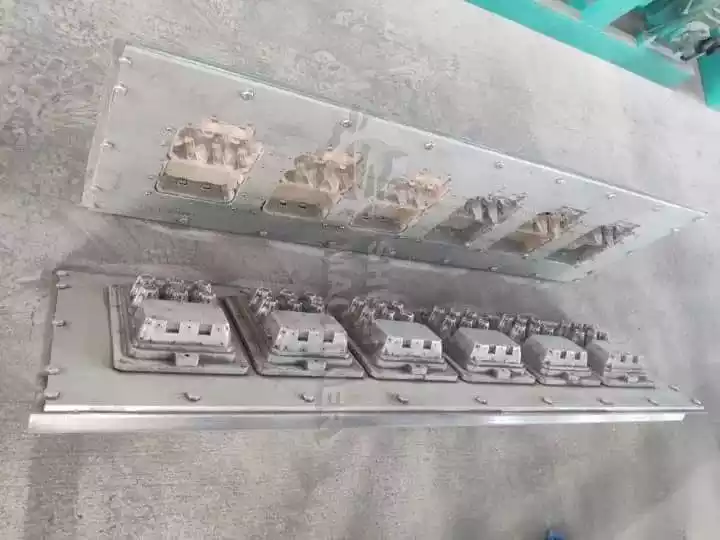

Moulds na usanidi: kuamua bei ya mwisho

Nyenzo ya mould (plastiki au alumini), chapa ya mota, ubinafsishaji wa voltage, na kiwango cha uendeshaji wa moja kwa moja vyote huathiri bei ya jumla. Mould za alumini zinatoa maisha marefu ya matumizi na bidhaa zenye muonekano mzuri zaidi lakini zina gharama ya juu. Uendeshaji wa juu wa moja kwa moja hupunguza gharama za kazi lakini unahitaji uwekezaji mkubwa wa vifaa.

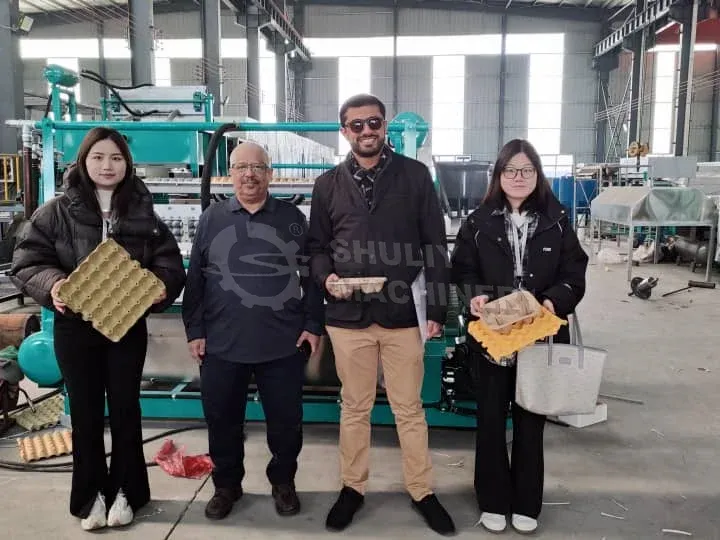

Kwa nini uchague mashine ya kutengeneza sahani za mayai ya Shuliy?

Kama mtengenezaji maalumu wa mashine za sahani za mayai mwenye uzoefu wa kuuza nje zaidi ya muongo mmoja, Shuliy hutoa bidhaa kwa zaidi ya nchi 60. Faida zetu ni pamoja na:

- Suluhisho moja kwa moja zinazojumuisha kuganda karatasi, kuunda, kukausha, na ufungaji

- Uzalishaji unaoweza kubinafsishwa, voltage, na moulds kulingana na mahitaji ya mteja

- Msaada kamili baada ya mauzo, ikijumuisha usakinishaji wa mbali, utatuzi wa hitilafu, na mafunzo ya waendeshaji

- Bei moja kwa moja kiwandani kwa ufanisi mkubwa wa gharama na mapato ya haraka ya uwekezaji (ROI)

Slutsats

Vitu vinavyoathiri gharama ya mashine za kutengeneza sahani za mayai ni pamoja na uwezo wa uzalishaji, mbinu za kukaushia, usanidi wa mould, na viwango vya uendeshaji wa moja kwa moja. Kuchagua mtengenezaji mtaalamu ni muhimu.

Shuliy inawapa wateja vifaa vinavyofanya kazi kwa ufanisi, thabiti na msaada kamili kusaidia wewe kushika fursa mpya za biashara katika soko la ufungaji rafiki kwa mazingira.

Wasiliana nasi sasa kwa nukuu za kina na suluhisho zilizobinafsishwa!