SL-4*1 egg tray maker sold to Yemen for self-owned egg tray production

This customer is an individual user from overseas who wishes to start his own local egg tray production business.

To ensure the reliability and production efficiency of the selected equipment, the customer made a special trip to our Shuliy factory for a site visit, where they gained a detailed understanding of the molding quality and drying process.

After the visit, the customer confirmed the order for an SL-4*1 egg tray machine with an aluminum mold and a trolley drying system on the spot, which demonstrates high trust in our equipment.

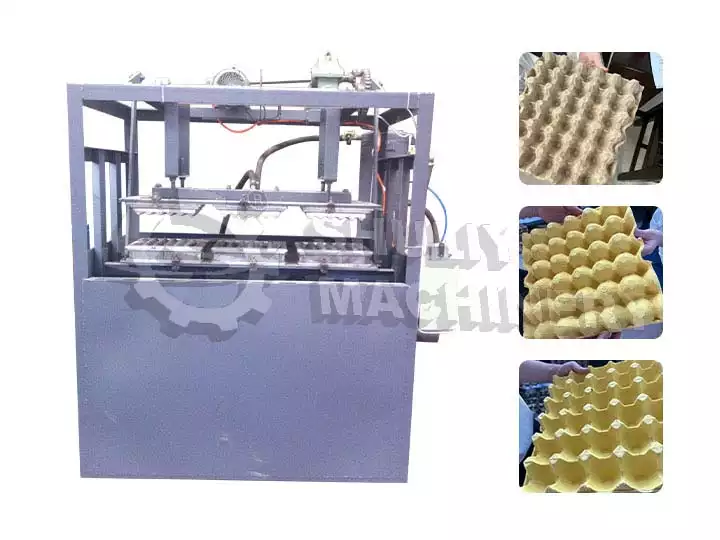

Equipment configuration

This SL-4*1 egg tray maker chosen by the customer belongs to the small pulp molding equipment, with a production efficiency of 1500pcs/h. It’s suitable for customers who do not have a big investment at the initial stage but are in pursuit of stable quality.

Mold selection

The machine is paired with an all-aluminum mold, and the mold parameters are as follows:

- Tray size: 300×300×50mm

- Grid number structure: 30 grids(5 × 6)

- Grid diameter and spacing: 45mm

- Customized engraving: GATRAY

Aluminum molds have higher durability and molding accuracy. It can keep the tray size consistent for a long time and meet the customer’s demand for branded logos.

Drying method

The Yemen customer chose the trolley drying system as the drying method, configured with two heating methods: burner + hot air oven. This match can be flexibly switched according to local energy conditions.

Compared with natural drying, this drying method is faster, less affected by the weather, and greatly improves the stability of production. It’s very suitable for individual factories or semi-automated operation scenarios.

Customer concerns and cooperation highlights

As the customer is the first time to build a factory, he pays extra attention to:

- Whether the equipment is easy to use.

- Whether the mold life is long.

- Whether the drying effect is stable.

We provided a detailed operation training program and assisted the customer with mold engraving and voltage customization (380V, 50Hz, 3-phase) to ensure that the equipment was ready for production.

The customer is satisfied with our service and professionalism and is looking forward to expanding the egg tray production scale in the future.

If you also want to know the detailed configuration of this small egg tray maker machine, please feel free to contact us for a quotation and technical proposal.