Egg Tray Production Line for Paper Tray Making

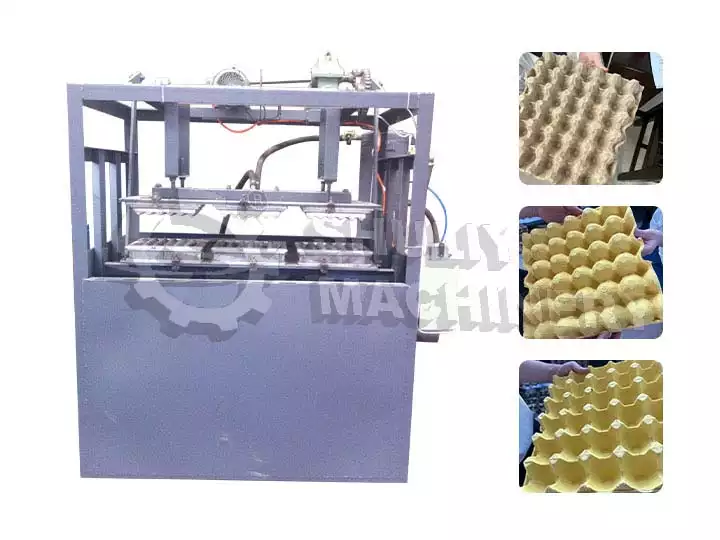

Egg Tray Forming Machine | Paper Tray Machine

Brand: Shuliy

Capacity: 1000-8000pcs/h

Final product: Egg tray, egg carton, fruit tray, nursery tray, wine tray, etc.

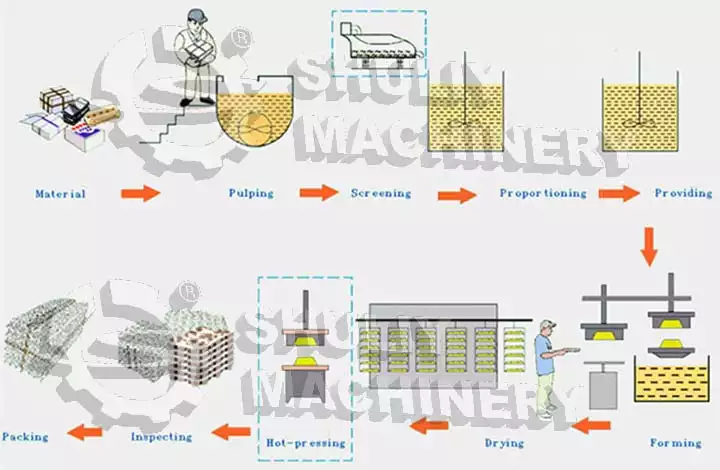

Egg tray manufacturing process: Paper pulping→molding→drying→hot pressing→packaging

Used equipment: Pulper, egg tray machine, egg tray dyer, hot pressing machine, baling machine

Egg tray drying methods: Natural drying, brick kiln drying, metal drying

The egg tray production line is an economical line that is very practical. This egg tray manufacturing plant is suitable for small, medium, and large-scale investors.

Besides, using this egg tray manufacturing machine is friendly to the environment because of its raw material. If you are interested in this business, welcome to contact us for more details!

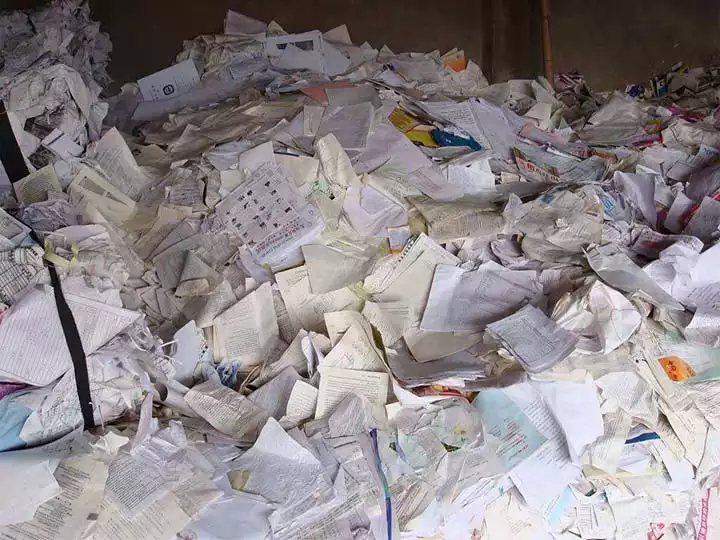

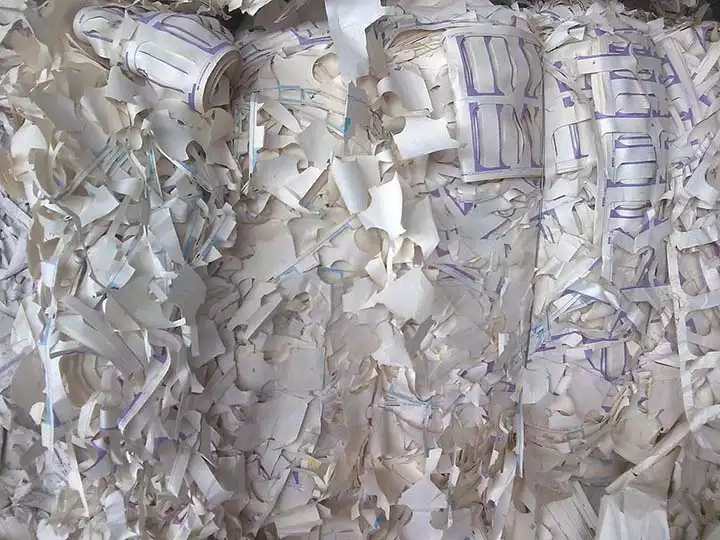

What material is used to make egg trays?

In fact, the raw materials are very common and cheap in the egg tray production line. There are a lot of raw materials produced in our daily life.

The raw materials are waste paper, waste magazines, waste books, waste cartons, etc.

Therefore, if you want to start a new business, egg tray making would be a good choice. Because of its abundant and low raw materials, it will reduce your production cost.

Introduction of the egg tray production line

As a leading manufacturer & supplier among egg tray making machine suppliers, our Shuliy Machinery has the complete and automatic egg tray making process.

If you are one of the egg tray suppliers, it’s necessary to learn this basic information.

Machines used in the egg tray production process

There are five machines used in this production line. The first one is the pulping equipment. The second one is the paper egg tray machine(key machine). The third one is the dryer. The fourth one is the hot pressing machine. The fifth one is the baling machine.

Paper egg tray manufacturing process

In the egg tray manufacturing process, totally four steps should be completed, in order to get quality egg trays.

- the pulp making machine: this kind of pulper is a hydra pulper, adopting the hydraulic power to crush wastes into the pulp, preparation for the next step. By the way, if you want an attractive color for the egg tray, you can add the additives.

- the egg tray machine: this pulp egg tray making machine is the core part of the whole line. This pulp egg tray machine has various types. It functions to mold the egg tray. Please contact us for more details!

- the dryer: from the machine name, it’s easy to understand that this machine is for drying the egg tray. But there are three types of drying methods: ①natural drying; ② brick drying; ③ egg tray drying machine. You can choose the suitable method according to your business scale. Also, our sales manager will provide great solutions to meet your demands!

- the hot pressing machine: this machine is mainly to press the egg tray, in order to get more beautiful and attractive egg trays.

- the baling machine: it’s used for baling the egg trays to stock easily.

Pay attention, during the egg tray production line, there are several water pools required. But we will provide suitable water pool drawings complying with the customers’ businesses.

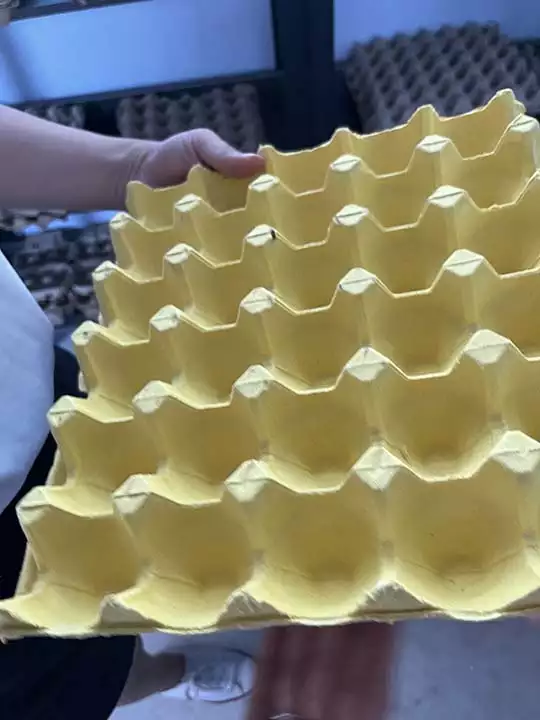

Egg tray description

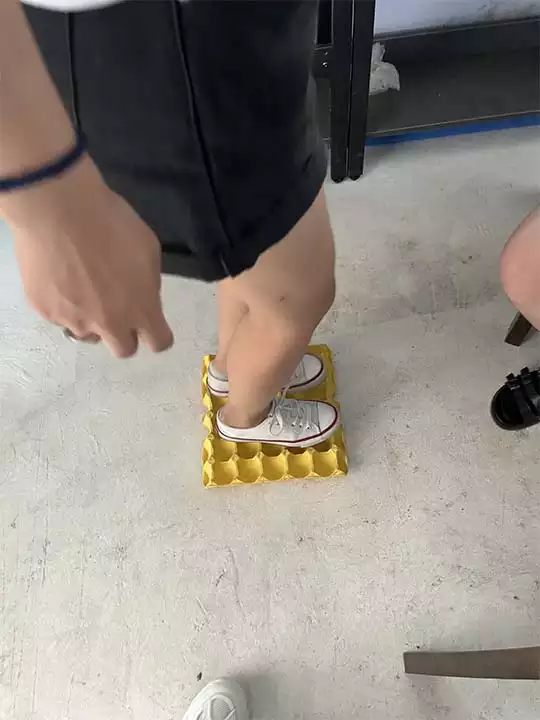

The egg trays produced by the automatic egg tray machine are not only light in weight but also reliable in quality.

The quality is reliable because there is no damage to the egg tray even if a person stands on it.

Besides, the color of the egg tray is also various. There are the usual colors such as earth pulp, purple, yellow, white, etc. If you have a specific color in mind, the rotary egg tray machine can also produce it for you.

Spotlights of the egg tray production line

- Environmental friendly. Due to its raw materials, pollution is reduced to some extent. For the current environment, it plays a big role.

- Low cost. As we know, it used waste paper, waste magazines, waste books, etc. For the new investor, it’s easy to acquire, and the price is cheap.

- Automation. We classify the egg tray making process based on the drying methods. The fully automatic egg tray machine and the manual egg tray making machine both are available. You can choose what suits your business.

- Convenient and quick. If want to start this egg tray production line, you just buy the required machines from us Shuliy Machinery. And then you can start it quickly! This results in a short investment period, and quick revenue.

- Labor-saving. Because of the high automation, you only arrange several laborers to look after the machine running. It greatly saves the labor cost.

What affects the cost of the egg tray machine?

- Business scale. As the business scale affects the machine capacity. If you are in the large-scale egg tray production line, you should purchase the corresponding machines to satisfy your business.

- Automation. Because the automation determines which drying method is applied. The natural drying, brick drying, and drying machine are definitely at different prices.

- Required time. In the international market, the exchange rate always varies.

Why choose the egg tray production line from Shuliy Machinery?

- Professional staff. Our sales manager has the professional knowledge to introduce the egg tray machine to our customers and answer their questions.

- Buy the required machines at once. As an outstanding company, we have various machines to meet the customers’ demands. You can buy what you need at one, which is very convenient.

- Famous brand. Our egg tray machines are exported to various foreign countries and regions, such as Zambia, the Philippines, Indonesia, Nigeria, Mocorro, etc.

How to use the egg tray production line safely for a long time?

- Before starting work, carefully check each part of the production line to ensure it is error-free.

- During the working process, pay attention to the working performance of the machine as well as the working condition. If there is something wrong, stop working immediately.

- After the work is finished, the machine should be cleaned, especially the pulp making machine and egg tray machine molds, so that they are kept in good condition and prolong the service life.

Successful case: automatic egg tray production line sold to Zambia

The Zambian customer is specialized in producing various types of paper trays for sale locally. Therefore, he was very interested when he browsed our website, which was very suitable for his needs. Through WhatsApp, we made contact.

After knowing the information about the machine, including the working video, mold, parameters, price, etc., we signed the contract immediately. Both sides cooperated very well.

Technical parameters of the egg tray machine

| Model | Capacity | Paper consumption | Water consumption | Energy used | Worker |

| SL-3*1 | 1000-1500pcs/h | 120kg/h | 300kg/h | 32kW/h | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/h | 45kwW/h | 3-4 |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/h | 58kW/h | 4-5 |

| SL-4*4 | 3000-3500pcs/h | 280kg/h | 560kg/h | 78kW/h | 4-5 |

| SL-4*8 | 4000pcs/h | 320kg/h | 600kg/h | 80kW/h | 5-6 |

| SL-5*8 | 5000pcs/h | 400kg/h | 750kg/h | 85kW/h | 3-4 |

| SL-5*12 | 6000pcs/h | 480kg/h | 900kg/h | 90kW/h | 3-4 |

| SL-6*12 | 8000pcs/h | 640kg/h | 1040kg/h | 100kW/h | 3-4 |

FAQ of Shuliy egg tray production line

Q: Will there be any effect when there are more impurities in the raw material?

A: Some lime and bagasse can be added to the raw material to increase the hardness of the egg tray. Wand when there are more impurities, a vibrating sieve can be added to remove impurities. (Vibrating sieve is used when a large-size egg tray production line is available.)

Q: Will the mold of the egg tray machine wear out in the production process?

A: If there are more impurities, the wear will be bigger, but in general the wear is small.

Q: If a customer wants a regular egg tray and also wants a shaped tray, can the molds be replaced?

A: You can use one machine, just change the mold.

Q: How many water pools does the customer need to build by himself?

A: It depends on the customer’s production and plant area. If it is a small production, 2-3 pools are enough. If the production is larger, there are 3-4 pools. Don’t worry, we will provide the drawings.